en

+

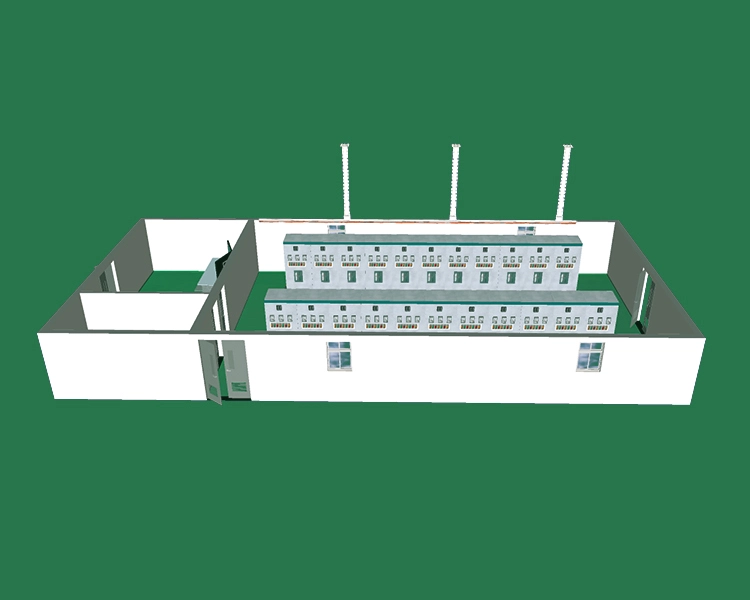

Substation integrated automation is an important technology in modern power systems, which aims to monitor, control and manage substation equipment through automation. Its goal is to improve the safety, reliability and economy of substations and ensure the efficient operation of power systems. Substation integrated automation systems usually consist of multiple subsystems, including functional modules such as data acquisition and processing, equipment monitoring, fault detection, and information transmission.

I. Composition of substation integrated automation

Substation integrated automation systems mainly consist of the following components:

1. Equipment monitoring system: Real-time monitoring of equipment in substations, including transformers, circuit breakers, switchgear, etc., through various sensors and instruments.

2. Data acquisition and processing system: Responsible for collecting various operating parameters of equipment in substations (such as current, voltage, frequency, power, etc.), and real-time processing and analysis of these data.

3. Communication system: Realize data transmission between various equipment in substations and monitoring centers to ensure fast and accurate transmission of information.

4. Control system: including the automation control function of the equipment, and realizing remote operation and control of the substation equipment through the automation system.

5. Safety protection system: ensuring the safe operation of the substation, including the monitoring of equipment status, fault alarm and emergency handling functions.

II. The concept of five remotes

The "five remotes" in the comprehensive automation of substations refer to telemetry, telesignaling, remote control, remote adjustment and remote viewing. They are important components of modern substation automation and can effectively improve the automation level and operation efficiency of substations.

1. Remote Measurement

Telemetry refers to the process of measuring various parameters in the substation in real time through remote equipment and transmitting data to the monitoring center. The main functions include:

- Data acquisition: collecting current, voltage, power, temperature and other data in the substation through sensors, instruments and other equipment.

- Data transmission: transmitting the collected data to the monitoring system through the communication network.

- Real-time monitoring: The monitoring system analyzes the collected data in real time to provide a basis for operation decisions.

The implementation of telemetry improves the substation's ability to monitor the status of equipment and helps operators to find potential problems in a timely manner.

2. Remote Signal

Remote signal refers to the transmission of status information of substation equipment through remote signals, such as the switch status of the equipment, fault signals, etc. The main functions include:

- Status monitoring: Real-time monitoring of the operating status of substation equipment to determine whether the equipment is in normal working condition.

- Fault alarm: When a device fails, the remote signal system can transmit the fault signal to the monitoring center in time to help operators respond quickly.

- Information feedback: Feedback information on equipment status changes to the monitoring system to provide a basis for decision-making.

The implementation of remote signaling helps to achieve rapid judgment of equipment status and fault handling, and improve the operating safety of substations.

3. Remote Control

Remote control refers to the process of controlling equipment in a substation through remote operation, including the start, stop, and switching of equipment. The main functions include:

- Remote operation: Through the monitoring system, operators can remotely operate the equipment in the substation to achieve control of the start, stop, and switching of equipment.

- Automated control: Combined with the automated system, remote control can automatically perform operations under certain conditions and improve operating efficiency.

- Fault handling: When a fault occurs, the operator can remotely isolate or switch the faulty equipment to ensure the safe operation of the system.

Remote control technology improves the operational flexibility and response speed of the substation and reduces the reliance on manual operation.

4. Remote Adjustment

Remote adjustment refers to the process of adjusting the parameters of substation equipment by remote means, including voltage adjustment of transformers. The main functions include:

- Parameter setting: Remotely set and adjust the operating parameters of the equipment through the monitoring system.

- Dynamic optimization: Dynamically adjust equipment parameters according to the system operating status to improve operating efficiency.

- Load management: When the load changes, adjust the operating status of the equipment in time to ensure the balance and stability of the system.

Remote adjustment technology can improve the operating efficiency and flexibility of the substation and optimize the configuration of power resources.

5. Remote Vision

Remote Vision refers to the process of visually monitoring the equipment and environment in the substation through remote monitoring means. The main functions include:

- Video monitoring: Real-time monitoring of the substation's operating environment through cameras and other equipment.

- Visual display: Display the operating status and environmental information of the substation equipment to the operator through a visual interface.

- Abnormal detection: Timely discover abnormal conditions of equipment and environment through video monitoring, so as to facilitate the adoption of corresponding measures

Remote viewing technology can enhance the monitoring capability of substations and improve the response speed to emergencies.

III. Advantages of integrated automation of substations

The integrated automation system of substations combines five remote technologies and has the following advantages:

1. Improve operating efficiency: Reduce manual intervention and improve equipment operating efficiency through automated monitoring and control.

2. Reduce operating costs: The automation system reduces the need for on-site operators, thereby reducing labor costs.

3. Enhance safety: Real-time monitoring and fault alarm functions can improve the safety of equipment and reduce the probability of accidents.

4. Optimize management: Data collection and analysis functions provide strong support for operation management and help optimize the allocation of power resources.

5. Improve reliability: The automation system can respond to faults quickly and ensure the stability and reliability of power supply.

IV. Future development trends

With the advancement of technology, the future development trends of substation integrated automation systems are mainly reflected in the following aspects:

1. Intelligence: With the development of artificial intelligence and big data technology, substation automation systems will become more intelligent and capable of self-learning and adaptive adjustment.

2. Networking: The application of Internet and Internet of Things technologies will enable substation integrated automation systems to have stronger interconnection capabilities and achieve more extensive data sharing and collaborative work.

3. Integration: Future automation systems will be more integrated, integrating multiple functions such as monitoring, management, and control to improve the overall efficiency of the system.

4. Greening: With the popularization of renewable energy, substations will consider environmental impacts more, and automation systems will optimize energy use and reduce carbon emissions.

5. Improved security: In the context of increasingly important network security, substation automation systems will pay more attention to information security and protection measures to ensure the safe operation of the system.